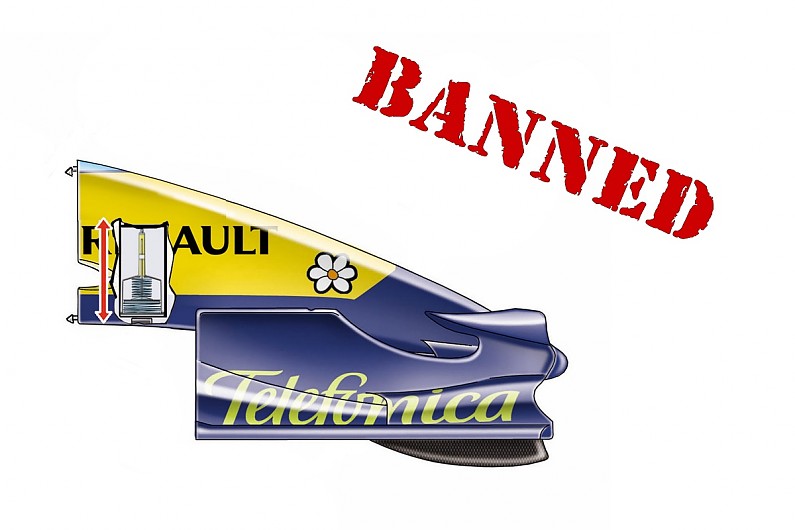

The ‘mass damper’ adopted by Renault for its 2005 R25 Formula 1 car was a stability aid that improved front-end downforce before it was outlawed by the FIA.

Devised at the height of Renault’s mid 2000s success, with Fernando Alonso scoring back-to-back titles in 2005 and ’06, the ‘mass damper’ was a simple solution that exemplified F1’s proclivity for lateral thinking to find a way around a problem.

Autosport’s technical expert Tim Wright, who worked for the Enstone-based team in the R&D department at the time, recalls that the device – situated in the nosecone – improved the stability of the front-end in cornering and inspired more confidence from Alonso and team-mate Giancarlo Fisichella.

“Basically it was a big weight inside a tube with a spring on either side, so when the car started to move up and down, it would react against that,” says Wright. “It was nothing particularly trick, but the drivers were over the moon with it.

“You can imagine if the car is stable going through a corner, it just gave them so much more confidence.

“It would definitely be circuit-dependent, but where it came into its own was bumpy circuit with lots of kerbs, it just calmed the front of the car down completely.

“I would say it was worth at least a second. It was a big, big change to the car.”

New rules introduced for 2005 that lifted the front wing by 50mm to reduce downforce and cornering speeds required teams to run an excessive amount of front spring stiffness to make up for the reduction in performance and keep the front wing as close as possible to the ground. This set off an unwanted bounce effect when the car was in pitch, which prompted Renault to seek a fix.

Cars of the period could make the 600kg weight limit (increased to 605kg for qualifying) relatively easy by comparison with their modern heavyweight counterparts, so ballast was often carried to bring the car up to the minimum weight.

“It calmed the front of the car down so that the front wing worked more efficiently, but essentially it was a mechanical piece of kit, the same as you have dampers and springs on the car” Tim Wright

This gave Renault license to install its mass damper solution. Devised by Rob Marshall, now Red Bull Racing’s chief engineering officer, it was a free moving weight suspended within a cylinder inside the nosecone that would act in opposition to the vertical forces applied to the car.

The benefits of such a device clearly had to exceed the additional weight that was being carried, especially as one of the drawbacks was its location: with ballast usually cited at the lowest possible point on the car to improve centre of gravity.

But extensive tests on the team’s seven-post shaker rig had already confirmed that a lap time gain was possible, not only settling the car, but also allow the drivers to attack the kerbs much harder, giving a more compliant ride and a more stable aerodynamic platform.

“A lot of testing went on with it before we could even think about putting it on a car,” recalls Wright.

“It had to be tuned properly, which meant a lot of research went into the weight and the springs and so on, but apart from that it was a tuneable device really.”

The mass damper was first installed towards the end of the 2005 season, Renault initially using a weight of around 10kg before it swiftly realised that this could be customised for each circuit.

Various weights were used to get the best from the car and a mass damper was latterly added at the rear of the car too, although Wright says this “wasn’t as effective”.

“We tried it, but the front was the dominant part because you’ve got the aero loading,” he says, “so the front of the car is the sensitive part and that’s where all the benefit came from.”

During this era of F1, there were two tyre suppliers – Bridgestone and Michelin, the latter supplying Renault. This was another coup for Renault, as it understood the Michelin rubber was more receptive to the use of the mass damper, as the tread block tended to move around more when exerted.

That wouldn’t stop others attempting to make similar gains though. Renault may have been the first, but others quickly followed suit and most of the field started employing mass dampers to varying degrees of success throughout 2005 and into ’06 with ever-more complex modality and weight.

It didn’t hamper Renault’s success however, as fresh from defeating Kimi Raikkonen’s McLaren in 2005, Alonso saw off Michael Schumacher’s Ferrari to win a second title in 2006, while the team won the constructors‘ title in both seasons.

But at the 2006 German GP, Renault faced a protest that its system equated to a ‘moveable aerodynamic device’. Although it was approved by the Hockenheim stewards, the decision was queried by the FIA, prompting Renault to race without the system to avoid the risk of disqualification.

Sure enough, in the Court of Appeal one month later the FIA moved to overturn the stewards’ decision. In its view, the escalation in development of the devices highlighted that their primary purpose was no longer to provide additional mechanical assistance but to markedly improve the car’s aerodynamic output.

“It’s one of these things a bit like the DAS system – is it really a steering issue?” says Wright. “You can argue it both ways and we tried very hard to argue that the mass damper was a mechanical aid rather than an aerodynamic aid.

“Yes, it calmed the front of the car down so that the front wing worked more efficiently, but essentially it was a mechanical piece of kit, the same as you have dampers and springs on the car.

“It was hardly an aerodynamic device, but it did help the aerodynamics.”

With Alonso departing for McLaren and Michelin pulling out of F1, requiring Renault to run Bridgestones in 2007, there were many more factors than merely the loss of the mass damper that explain its slump to third in the constructors‘ standings that season. But it was yet another factor the team could have done without.